Rotogravure Printing Cylinder Manufacturing Process

Jan 20, 2024

Singla Engravures LLP is equipped with a modern manufacturing base and sophisticated equipment in Ghaziabad (Delhi/NCR) to ensure high-quality rotogravure cylinder production. The process involves several detailed steps, as outlined below:

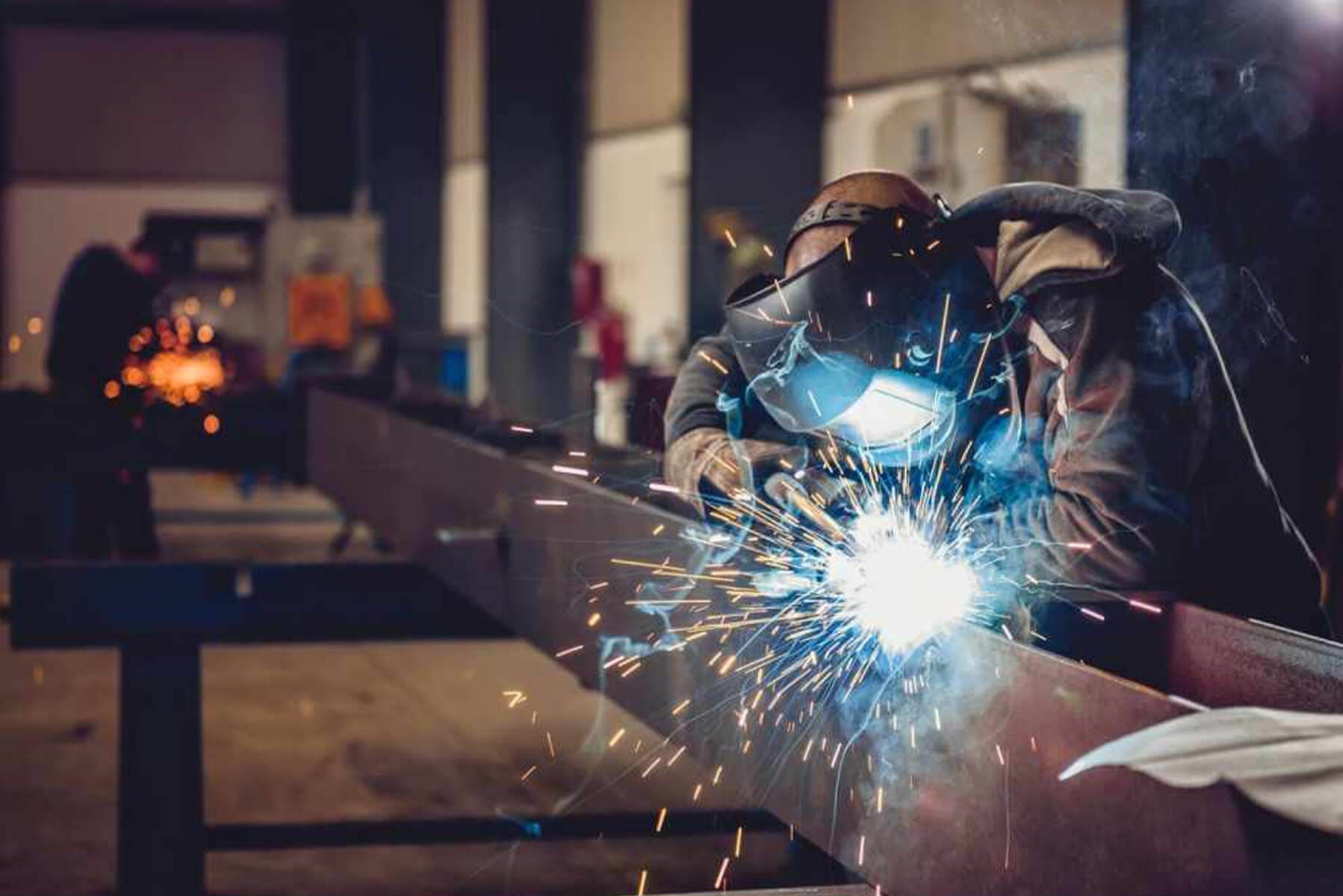

Step 1: Manufacturing

Singla Engravures LLP is equipped with the most modern manufacturing base and sophisticated equipment in Ghaziabad (Delhi/NCR), which guarantees a high level of quality at each stage of production. Processes such as in-house designing, pre-press operations, cylinder making, copper plating, engraving, polishing, and chrome plating are carefully supervised by experts. Our facility strikes the right balance of quality, innovation, and sustainability, catering to the evolving needs of the rotogravure market by producing high-quality cylinders for flexible, decorative, and specialty printing.

.avif)

Step 2: In-House Designing

To begin the rotogravure cylinder engraving process, the first step is creating the artwork in the form of an engraving that will be used on the rotogravure cylinder. This is handled by a design division within the organization that coordinates with customers to create a design that complies with project requirements. The designers use specialized tools to produce high-definition images and patterns that will later be engraved on the copper-coated cylinder. This phase is crucial, as it sets the foundation for the entire production process, ensuring the final engraved design is both attractive and efficient for printing. Once the design process is complete, the design moves to the pre-press stage.

Step 3: Pre-Press

During the pre-press process, the artwork designed in the previous stage is prepared for engraving. The purpose of this step is to format the artwork so that it can be exported to the engraving machine. At this stage, images can be edited with modifications such as color adjustments, tone corrections, and alignment to ensure they are ready for engraving and printing. If applicable, color separations, silkscreen adjustments, and halftone corrections are made to fit the design onto the surface of the printing cylinder. Following this process helps the pre-press technician optimize the design for reproducing the final product.

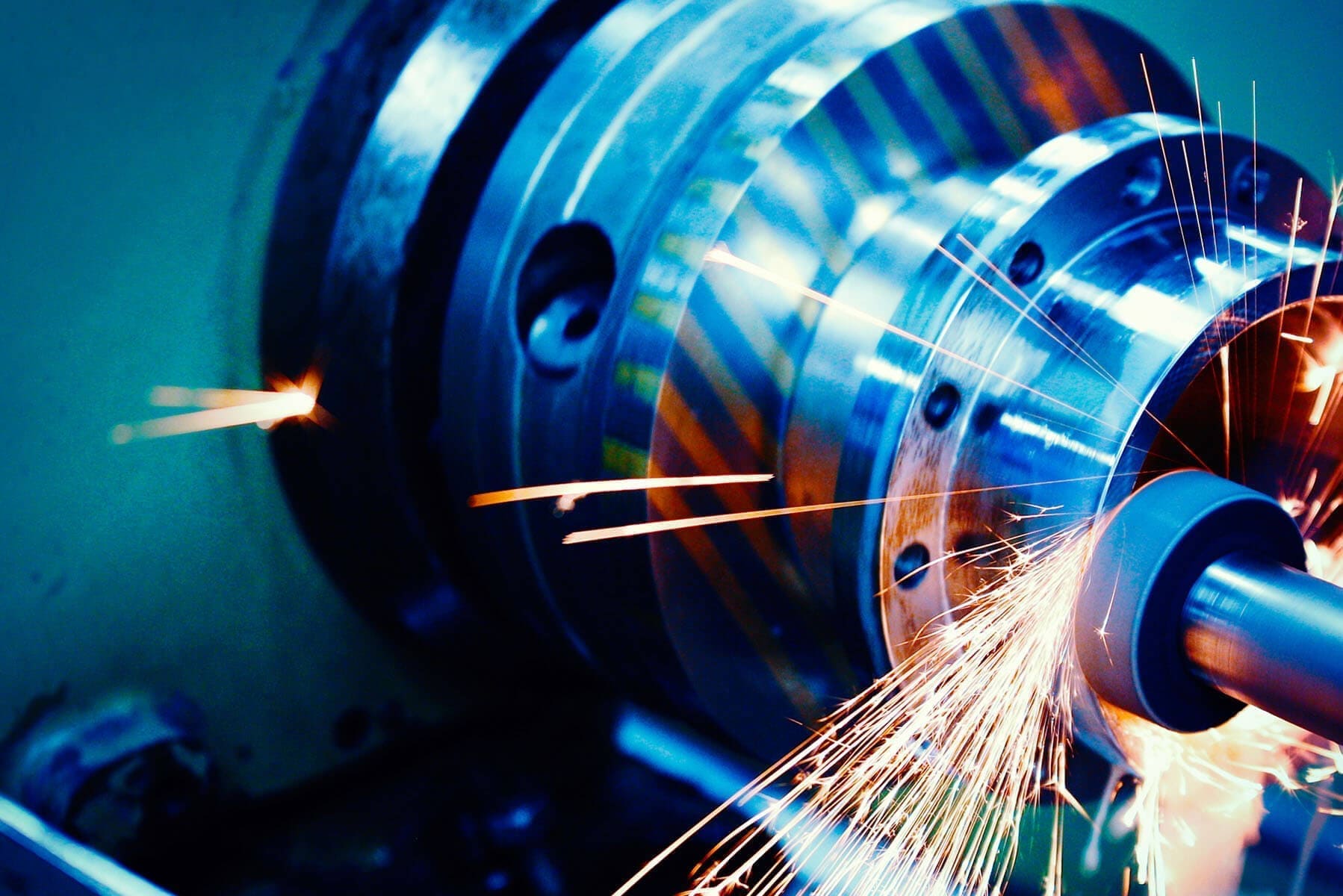

Step 4: Cylinder Making

The matrix shell, or base cylinder, is manufactured in-house to closely monitor quality. This cylindrical component serves as the platform upon which all other operations are performed and is made of either steel or aluminum. The prototype cylinder is developed based on the printing parameters. A rectifying cylinder must be perfectly cylindrical and smooth to prevent any disturbance to the quality of work during the cylinder preparation stage. This internal production enables the cylinder to be made according to the specific quality requirements of printing, eliminating the need to rely on external manufacturers.

Step 5: Copper Plating

Following the manufacture of the base shell, it undergoes a process of electroplating with copper. The cylinder is immersed in a zinc plating solution where a layer of copper is deposited over a pre-coated surface. Copper has been chosen because it has a soft surface yet is sturdy enough for engraving work. It is crucial to control the thickness of the copper layer, as this affects both the draft of the engravings and the strength of the cylinder during abridged printing. For the engraved design to turn out well, the copper coating must be even and free of foreign particles. After plating, the cylinder is inspected to ensure that the copper layer has achieved the predetermined thickness and quality.

Step 6: Engraving & Mezzotint Copper

With the copper plating complete, the engraving process can begin. The design is engraved on the copper surface using computer-aided engraving systems. This delicate work involves the engraving machine recalling the digital file from the pre-press stage and painstakingly reproducing the design on the copper surface. The width and depth of the engraved lines are controlled accurately, as they correspond to the areas that will be filled with ink during printing. After engraving, the cylinder undergoes polishing to enhance the surface finish and remove any irregularities. Careful polishing ensures that the line edges are clean and sharp, which is essential for producing prints of exceptional quality.

Step 7: Chrome Plating

Vinyl-cut cylinders are electroplated with a chrome finish after engraving and polishing. The purpose of chrome plating is to protect the printed copper surface from abrasion during use. Without chromium plating, the printed copper would wear off easily, significantly shortening the lifespan of the cylinder. The benefits of chrome plating extend beyond enhanced tensile strength; it also provides improved anti-rust properties and reduces friction during printing. To ensure optimal functionality of the cylinder in the printing machine and to prevent premature failure of the chrome, the chrome layer must be smooth and free of defects when applied. After chrome application, quality control is conducted to focus on maintaining the cylinder’s shape.

Step 8: Proofing

The proofing stage is defined as the point at which the cylinder is approved for mass production. During this phase, the engraved cylinder is placed in a press to determine if the design has been engraved as required and if the print quality is acceptable before moving into mass production. This stage is crucial as it allows for the correction of any mistakes or flaws that may have occurred during the engraving or plating processes. Any defects, positioning errors, or color inaccuracies in the images, as well as surface defects, are addressed, and a new proof is produced to evaluate the effectiveness of the amendments.

Step 9: Quality Control (QC)

Once proofed and deemed complete, every cylinder undergoes a thorough quality control (QC) process. During QC, the cylinder is assessed for any inaccuracies that may have been overlooked earlier, such as engraving irregularities, chrome plating issues, or deficiencies in the base shell structure. Precise instruments are used to measure the cylinder’s surface areas, engraving depths, and overall dimensions. Everything related to the cylinder must adhere to specified technical and quality standards. Consequently, all thermally coated cylinders dispatched for shipment must pass these quality control requirements.

Step 10: Dispatch

Once the cylinder has successfully passed all quality control inspections, it is prepared for dispatch from our facility in Ghaziabad (Delhi/NCR). Special care is taken to ensure that the cylinder is packed securely with adequate padding to prevent any damage during transport, ensuring it arrives in good condition. The dispatch process is precise and straightforward to guarantee timely delivery to the client. At this stage, the cylinder is thoroughly prepared for the printing process, where it will play a crucial role in producing high-quality prints for extended print runs.

.jpg)

.avif)